Solutions

- Home

- Solutions

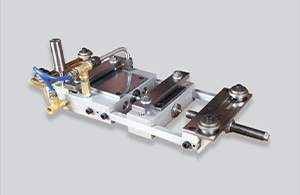

The main constructional characteristics of Press Room feeders are Rigid & Strong Structure with minimal wear characteristics, mounted as close as possible to the die set or on the die in case of thin strips Durability (all sliding components are hardened or hard-chrome plated – pistons in stainless steel – hard brass cylinder lines to avoid oxidation problem) Very High Pitch Accuracy because of powerful front and rear shock absorbers Quiet Low Air Consumption & Inexpensive Simple Installation (it is an interchangeable component from one die set to the other) Pneumatic Feeders to meet new competitive challenges in Speed / Accuracy / Reliability / Longer life. With an intense market research & practical experience in metal stamping based on regular market interaction, We have brought a range of Pneumatic Feeders to suit your exact requirement and application. Working on customer relations management theory, we offer a complete package of problem solving solution. Our field experience staff can help in setting your complete line & can guide you to select the perfect equipments & tooling. Press Room Pneumatic Feeders made from special alloy aluminium & are made in a modular way for automatic feeding of metallic & non metallic strips including paper, plastic, fiber, wires, tubing, extruded material.Technically advanced design, selection of finest material, combined with strict quality control manufacturing, has resulted in most reliable air feeds for Indian Tough Condition. Models available uptill 600mm wide, 5mm thick, 600mm pitch / stroke length.

Press Room Automation & Feed Fixtures Pvt. Ltd. is offering Spray Lubricating System from Die Tronic, Italy. Spray Lubrication System provide a highly efficient method of applying lubricants and corrosion protection fluids. In addition to lubricating blanks, coils, pipe sections and stamping or forming tools, wires and bars can also be treated. We know how important it is – especially today – to reduce production costs and our worldwide leadership in spray technology can help you operate more efficiently and save money. Precise control oflubricating applications can reduce oil consumption by up to 90 % and can eliminate time-consuming cleaning of parts. The Spray Lubrication System provides exact lubrication control for can and tab stamping processes. This unique system utilizes Low Volume Low Pressure technology to apply a fine, even film of lubricant to metal stock. The compact guns easily fit inside the press window and are cost-effective replacements for messy, inefficient pads and rollers. Each system includes two precision spray guns, one lubricant reservoir and the controller which regulates air pressure, lubricant flow and controls gun operation. Benefits Provides exact lubrication control Reduces oil use by up to 90% Significantly lowers reject rates Extends tool life Increased Press Speed because of reduction of Slug Pulling & Die Packing. Features Compact design; easy to install. Unique design uses Low Volume Low Pressure (LVLP) technology. Applies lubricant without waste, mist or overspray. Independent, instant response fluid flow controls for each gun. Once set, oil coverage stays consistent without further adjustment. The base unit consists of an air-operated diaphragm pump which draws the lubricating fluid from the container through a suction filter. Lubricant is pushed through the lines to the spray nozzles mounted in the coil lubricator using low pressure. Double air jets distribute the lubricant over the metal stock in a uniform film. It has pressure regulators from where Air & Oil pressure can be regulated as per requirement. An Oil ‘lank of 30 liter capacity is provided with visual inspection for minimum level. It has a Power management system to integrate with the press. It has a Panel with connectors for connecting up to 4 / 8 spraying valves KA2. SPRAY V.ALVE KA2 Ka2 nozzle valve is made of stainless steel with Viton seals. Adjusting the amount of oil is done through rear screw. Hat spraying range = 60 0 Nozzle and air cap = 1 mm

FEATURES The units are fabricated from steel and the straightener rolls are properly fixed and aligned in machine and ground housing. One/Two sets of drive pinch rolls are provided as required. All the feed Rolls & Bottom Rools are driven, while Top Rolls have individual / Gang adjustment, All the Rolls are made of Special Alloy Steel Material Hardened, Ground Chrome plated & are housed into precision needle bearing sealed ar both end. Roll setting scale on side plates/Dial gauges in some models. Entry Guides & Exit cascade rolls. Control Panel with Suitable loop control system to maintain loop of coil for the machine via Antenna Type loop Controls / limit through limit Switches. OPTIONS A.C. variable driven coil straightener are available on request. Ultrasonic / photoelectric loop controls. Remote pendant control (jog forward / reverse) Decoiler – Straightener mounting on common base. Inclined head mounting. Centralized lubrication system. For heavier thickness range,pinch rolls are operated pneumatically / hydraulically. Openable top straightener head blank mechanically or with Pneumatic / Hydraulic Cylinder.

Mechanical engineering is a diverse subject that derives its breadth from the need to design and manufacture everything from small individual parts and devices (e.g., microscale sensors and inkjet printer nozzles) to large systems (e.g., spacecraft and machine tools). The role of a mechanical engineer is to take a product from an idea to the marketplace. In order to accomplish this, a broad range of skills are needed. The mechanical engineer needs to acquire particular skills and knowledge. He/she needs to understand the forces and the thermal environment that a product, its parts, or its subsystems will encounter; to design them for functionality, aesthetics, and the ability to withstand the forces and the thermal environment they will be subjected to; and to determine the best way to manufacture them and ensure they will operate without failure. Perhaps the one skill that is the mechanical engineer’s exclusive domain is the ability to analyze and design objects and systems with motion. Mechanical Strategy The most likely cause is that prior to these profitable runs, was a period of mechanical-strategy-drawdown. Time and time again we see this pattern. The strategies have a short period of drawdown and everyone freaks out! So they quit, take a break, find another strategy, change their strategy or start skipping trades that don’t “feel good”. This is the WORST thing you can do when learning to trade a mechanical strategy. Frontiers of Research Since these skills are required for virtually everything that is made, mechanical engineering is perhaps the broadest and most diverse of engineering disciplines

Mechanical engineering is a diverse subject that derives its breadth from the need to design and manufacture everything from small individual parts and devices (e.g., microscale sensors and inkjet printer nozzles) to large systems (e.g., spacecraft and machine tools). The role of a mechanical engineer is to take a product from an idea to the marketplace. In order to accomplish this, a broad range of skills are needed. The mechanical engineer needs to acquire particular skills and knowledge. He/she needs to understand the forces and the thermal environment that a product, its parts, or its subsystems will encounter; to design them for functionality, aesthetics, and the ability to withstand the forces and the thermal environment they will be subjected to; and to determine the best way to manufacture them and ensure they will operate without failure. Perhaps the one skill that is the mechanical engineer’s exclusive domain is the ability to analyze and design objects and systems with motion. Mechanical Strategy The most likely cause is that prior to these profitable runs, was a period of mechanical-strategy-drawdown. Time and time again we see this pattern. The strategies have a short period of drawdown and everyone freaks out! So they quit, take a break, find another strategy, change their strategy or start skipping trades that don’t “feel good”. This is the WORST thing you can do when learning to trade a mechanical strategy. Frontiers of Research Since these skills are required for virtually everything that is made, mechanical engineering is perhaps the broadest and most diverse of engineering disciplines

Mechanical engineering is a diverse subject that derives its breadth from the need to design and manufacture everything from small individual parts and devices (e.g., microscale sensors and inkjet printer nozzles) to large systems (e.g., spacecraft and machine tools). The role of a mechanical engineer is to take a product from an idea to the marketplace. In order to accomplish this, a broad range of skills are needed. The mechanical engineer needs to acquire particular skills and knowledge. He/she needs to understand the forces and the thermal environment that a product, its parts, or its subsystems will encounter; to design them for functionality, aesthetics, and the ability to withstand the forces and the thermal environment they will be subjected to; and to determine the best way to manufacture them and ensure they will operate without failure. Perhaps the one skill that is the mechanical engineer’s exclusive domain is the ability to analyze and design objects and systems with motion. Mechanical Strategy The most likely cause is that prior to these profitable runs, was a period of mechanical-strategy-drawdown. Time and time again we see this pattern. The strategies have a short period of drawdown and everyone freaks out! So they quit, take a break, find another strategy, change their strategy or start skipping trades that don’t “feel good”. This is the WORST thing you can do when learning to trade a mechanical strategy. Frontiers of Research Since these skills are required for virtually everything that is made, mechanical engineering is perhaps the broadest and most diverse of engineering disciplines

Mechanical engineering is a diverse subject that derives its breadth from the need to design and manufacture everything from small individual parts and devices (e.g., microscale sensors and inkjet printer nozzles) to large systems (e.g., spacecraft and machine tools). The role of a mechanical engineer is to take a product from an idea to the marketplace. In order to accomplish this, a broad range of skills are needed. The mechanical engineer needs to acquire particular skills and knowledge. He/she needs to understand the forces and the thermal environment that a product, its parts, or its subsystems will encounter; to design them for functionality, aesthetics, and the ability to withstand the forces and the thermal environment they will be subjected to; and to determine the best way to manufacture them and ensure they will operate without failure. Perhaps the one skill that is the mechanical engineer’s exclusive domain is the ability to analyze and design objects and systems with motion. Mechanical Strategy The most likely cause is that prior to these profitable runs, was a period of mechanical-strategy-drawdown. Time and time again we see this pattern. The strategies have a short period of drawdown and everyone freaks out! So they quit, take a break, find another strategy, change their strategy or start skipping trades that don’t “feel good”. This is the WORST thing you can do when learning to trade a mechanical strategy. Frontiers of Research Since these skills are required for virtually everything that is made, mechanical engineering is perhaps the broadest and most diverse of engineering disciplines

Mechanical engineering is a diverse subject that derives its breadth from the need to design and manufacture everything from small individual parts and devices (e.g., microscale sensors and inkjet printer nozzles) to large systems (e.g., spacecraft and machine tools). The role of a mechanical engineer is to take a product from an idea to the marketplace. In order to accomplish this, a broad range of skills are needed. The mechanical engineer needs to acquire particular skills and knowledge. He/she needs to understand the forces and the thermal environment that a product, its parts, or its subsystems will encounter; to design them for functionality, aesthetics, and the ability to withstand the forces and the thermal environment they will be subjected to; and to determine the best way to manufacture them and ensure they will operate without failure. Perhaps the one skill that is the mechanical engineer’s exclusive domain is the ability to analyze and design objects and systems with motion. Mechanical Strategy The most likely cause is that prior to these profitable runs, was a period of mechanical-strategy-drawdown. Time and time again we see this pattern. The strategies have a short period of drawdown and everyone freaks out! So they quit, take a break, find another strategy, change their strategy or start skipping trades that don’t “feel good”. This is the WORST thing you can do when learning to trade a mechanical strategy. Frontiers of Research Since these skills are required for virtually everything that is made, mechanical engineering is perhaps the broadest and most diverse of engineering disciplines