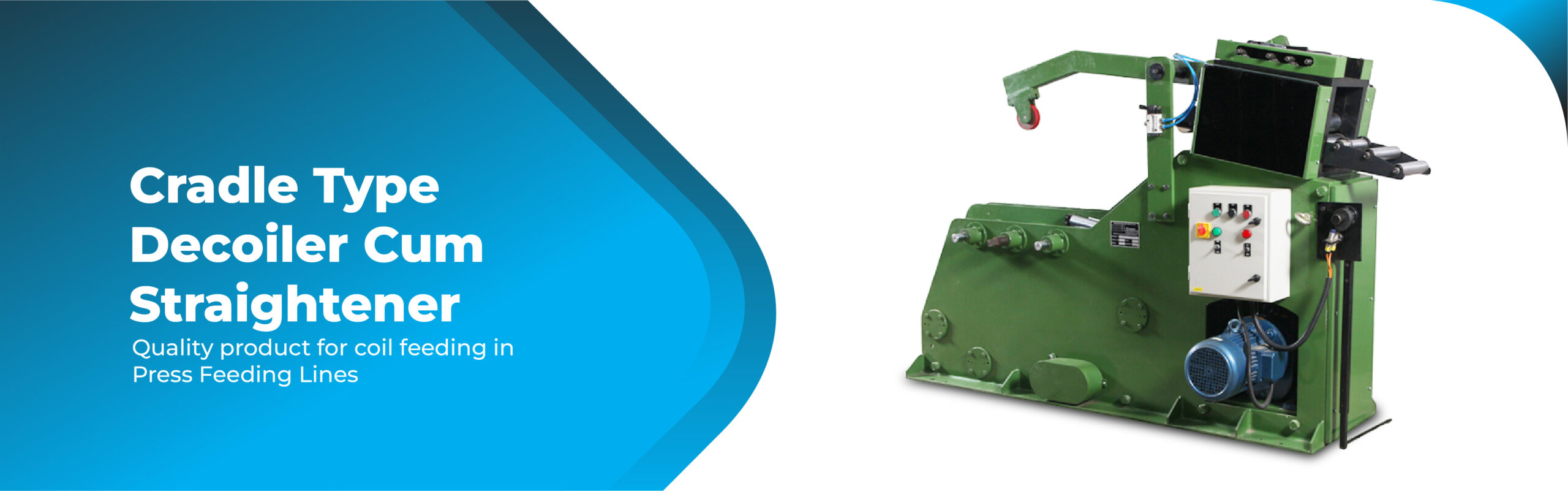

Cradle Type Decoiler Cum Straightener

Cradle straighteners offer a safe and simple solution for controlling heavy gauge and high tensile coils. For many years Press Room has offered various solutions to these problem applications. These Combination Cradle/Straightener Units provide for ease in loading.

The material is decoiled from the top and is driven into a slack loop in front of the straightener. A servo feed can be cabinet or press mounted to complete the feed line.

The system comprises of Cradle Unit along with driven Straightener mounted ahead of it. The feature of the system is that as they are mounted on same base structure, the alignment with respect to each other saving space & installation time.

The cradle rolls, straightener pinch rolls and lower straightening rolls are driven by a variable speed drive with loop control. All rolls are Hardened, Ground, and set in anti-friction bearings.

In coil cradle instead of expandable mandrel the coil is placed on driven rollers with adjustable side plates for centring. Coil cradle side plates with flared lead edge are independently adjusted. The side plates are optionally provided with side rollers for prevention of damage in sides for delicate coils.

Heavy Duty Models

The combination hold down wheel / peeler/threader/stock de-bender and exit thread table allow one operator to power thread material from the coil to servo feeder entry.

- Eight straightening rolls of 100 mm diameter

- Hydraulic Side Width guide

- Coil Hold Down Arm, Peeler, Threader and Stock De-Bender

- Hydraulic Pinch Station

- 5 Tons Heavy Duty Decoiler

We Can offer Special units Cradle Type Feeder Cum Straightener with a single or dual cradle.

Cradle Decoiler cum Straightener ( Standard Models )

Model Max. Coil

Weight

K.G.Max. Coil

Width

(mm)Thickness Range

(mm)Coil ID.

(mm)Max OD.

(mm)Power

(HP)Centre

Height

from

FloorOccup. Area (mm)

L. W. H.

CDS-1500-200-65-7 1500 200 1.0 To 3.0 450 1200 3.0 1100 2200X970X1315

CDS-1500-300-65-7 1500 300 1.0 To 3.0 450 1200 3.0 1100 2200X1170X1315

CDS-2500-300-80-7 2500 300 1.0 To 4.0 450 1200 5.0 1380 2800X1390X1350

CDS-2500-400-80-7 2500 400 1.0 To 4.0 450 1200 5.0 1380 2800X1590X1500

| Heavy Duty Hydraulic Cradle Decoiler cum Straightener ( Standard Models ) | ||||||||

|---|---|---|---|---|---|---|---|---|

| Model | Max. Coil Weight K.G. | Max. Coil Width (mm) | Thickness Range (mm) | Coil ID. Min. (mm) | Max OD. (mm) | Power (HP) | Centre Height from Floor | Occup. Area (mm) L. W. H. |

| HCDS-1500-200-100-7 | 1500 | 200 | 2 To 6 | 450 | 1200 | 5.0 | 1200 | 2500X1000X1450 |

| HCDS-5000-400-125-8 | 5000 | 400 | 2 To 10 | 500 | 1500 | 10.0 | 1345 | 4575X1560X2400 |

| HCDS-5000-600-125-8 | 5000 | 600 | 2 To 6 | 500 | 1500 | 10.0 | 1380 | 4600X1860X2450 |

All above equipment are designed for Line speed uptill 15 mtrs. per minute & material having tensile strength 40 kgf/mm max. Models of Higher Capacity or Higher Or Lower Line Speeds are available on request.

Technical specifications are indicative and subject to change to suit end application.